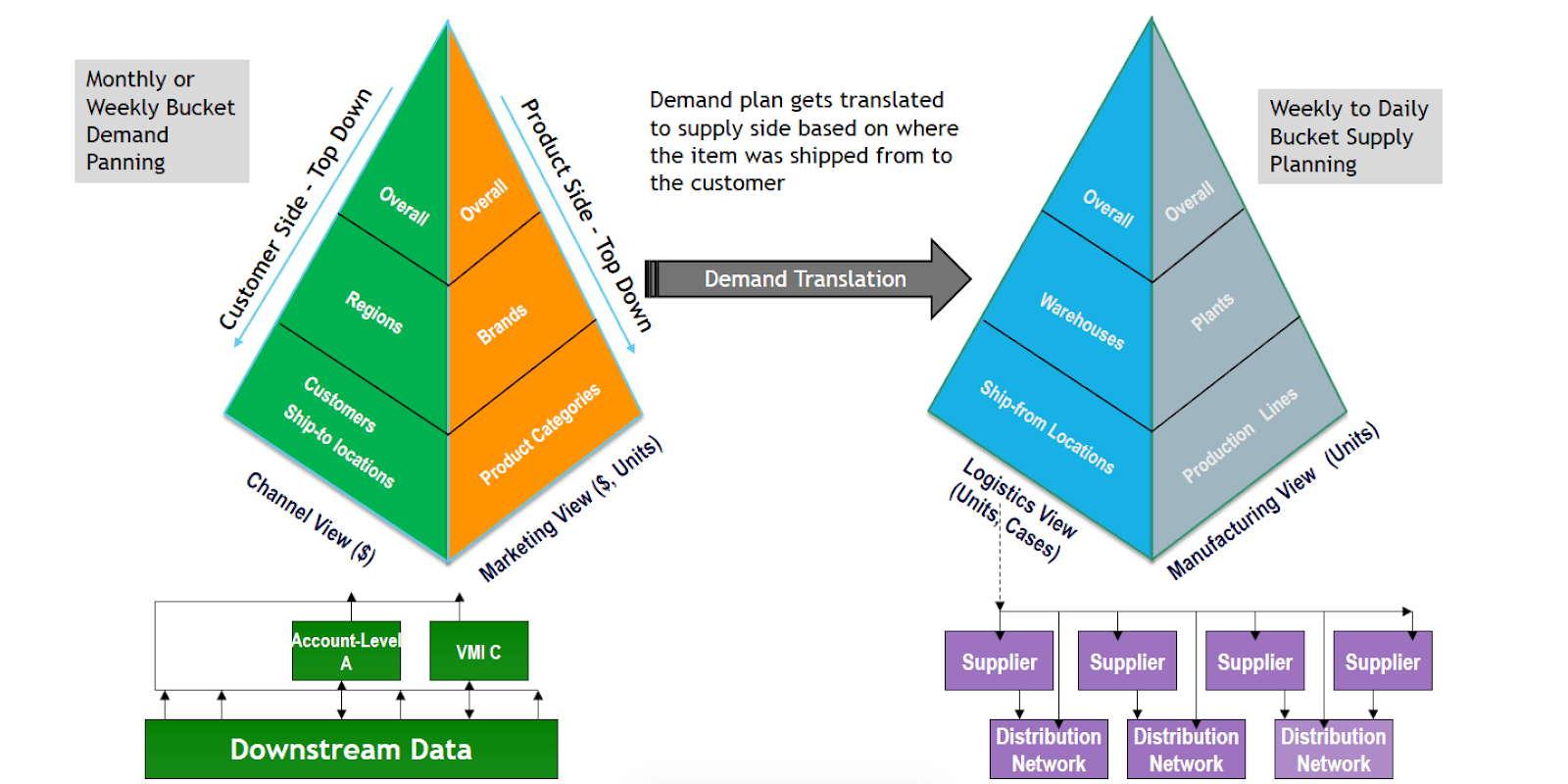

Supply planning is the component of supply chain management involved with determining how to best fulfill the requirements created from the demand plan. The objective is to balance supply and demand in a manner that achieves the financial and service objectives of the enterprise. A supply plan is another component of the Sales and Operations Planning (S&OP) process and is depicted on the right side of the demand and supply planning structure diagram below.

Supply Planning Process

The supply planning process commences with an approved demand plan. The demand plan is a sum of all the sales reviewed and approved channel, regional and/or customer forecasts.

The approved demand plan goes through a demand translation step. If you are using a supply chain planning software system, such as DemandCaster, the demand translation step will automatically allocate the demand plan to the location where the demand for a specific customer/item relationship is typically fulfilled.

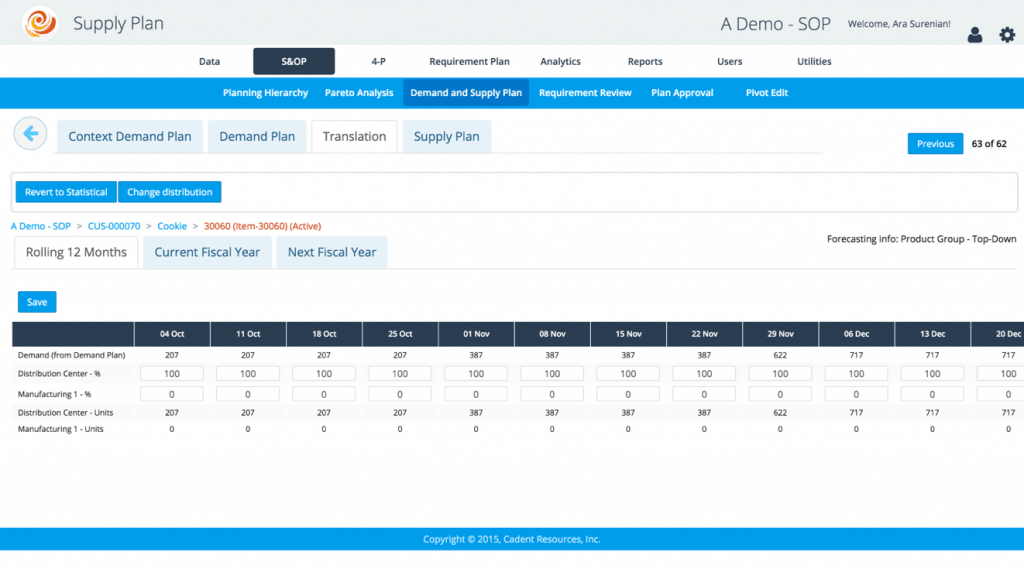

An automated software system should then use the customer orders record to identify the ship-from location and then generate a forecast to be applied against a specific ship-from location. As shown in the sample screen capture below, the software facilitates the capability to transition demand from one location to another by part. With DemandCaster, this transition can be done manually within the screen or automatically via location linking.

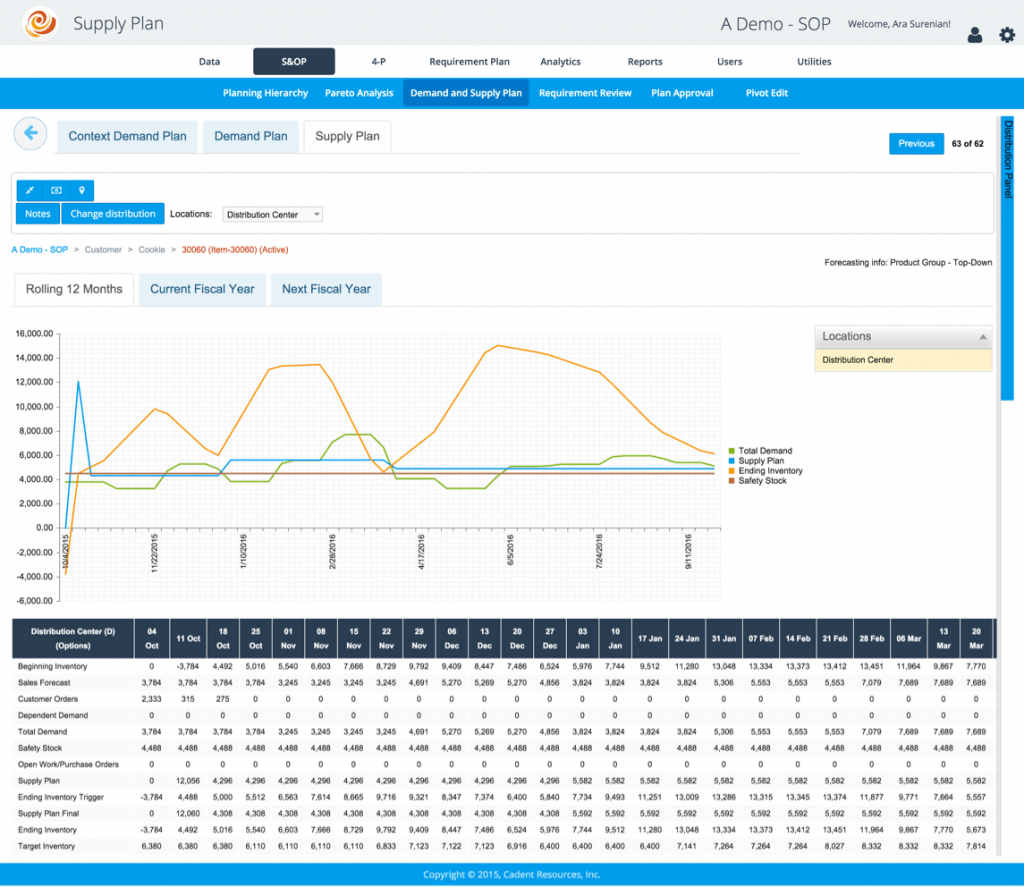

Once the translation step is complete, the supply plan is run to generate a finished goods master production schedule by item and by location. The supply plan includes all item related attributes and data such as on-hand quantities, open and planned customer orders, open and planned shop orders, lead times, minimum order quantities, safety stocks, level loading and demand chase.

Once the supply plan is complete, DemandCaster enables the user to run a requirements review and capacity review to assess the impact of the demand and supply plan on resources. If required, the plan may be changed to address any constraints.

Upon completing supply planning, the user approves the plan to generate the MPS that can be pushed back to the ERP for execution or used in DemandCaster to run day-to-day requirement planning and ordering.